Pastel extrusions, used for colored pencils, are laid by hand onto grooved wooden boards, where they will dry before being placed in pencil slats. The extruding machine that produced them usually handles a single color each week, after which it is scrubbed clean to prepare it for the next.

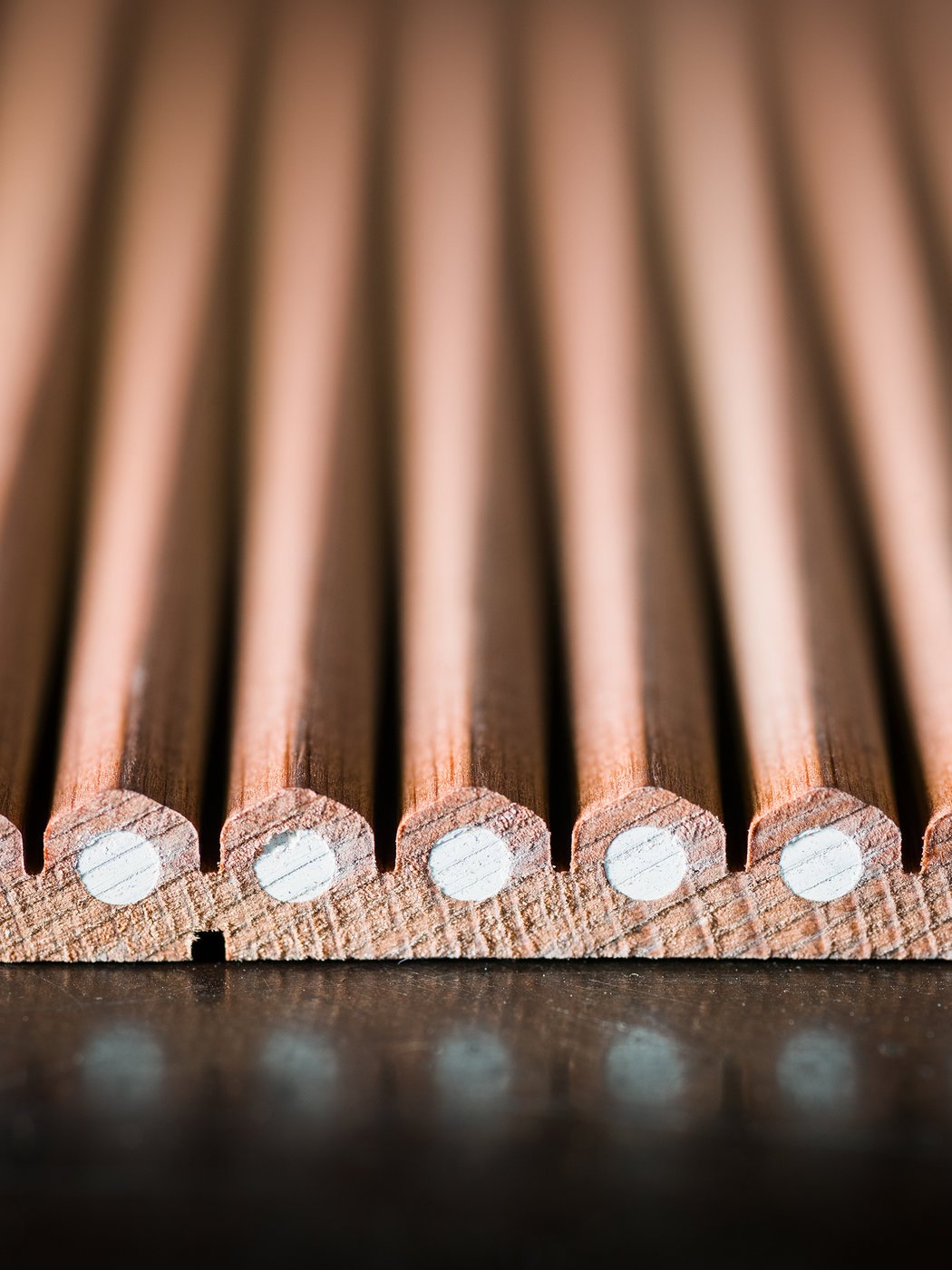

A lead layer drops graphite cores into pre-glued slats.

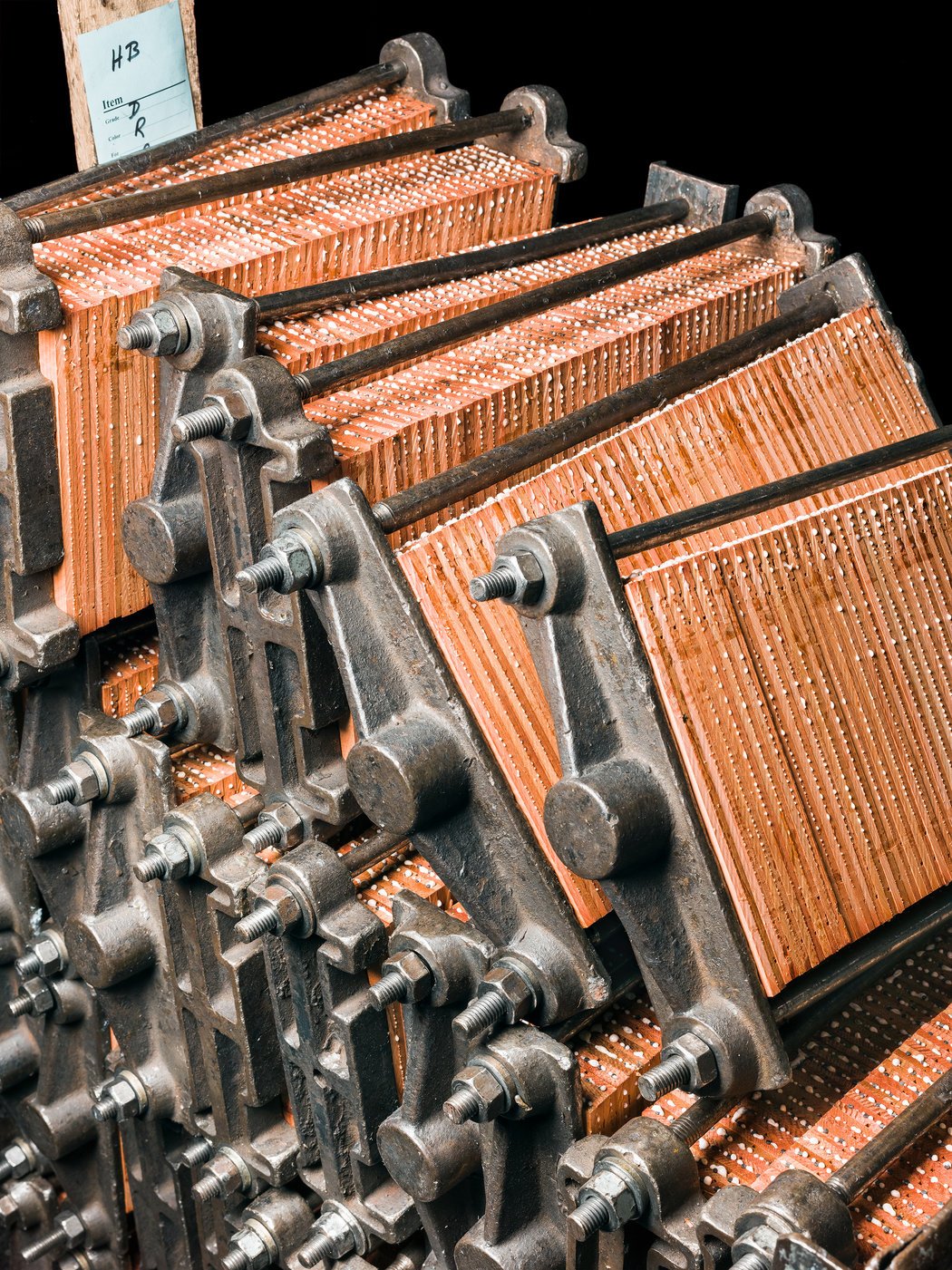

Another layer of wood fully encases the pencil’s core. The resulting “sandwich” is clamped together to bond and dry.

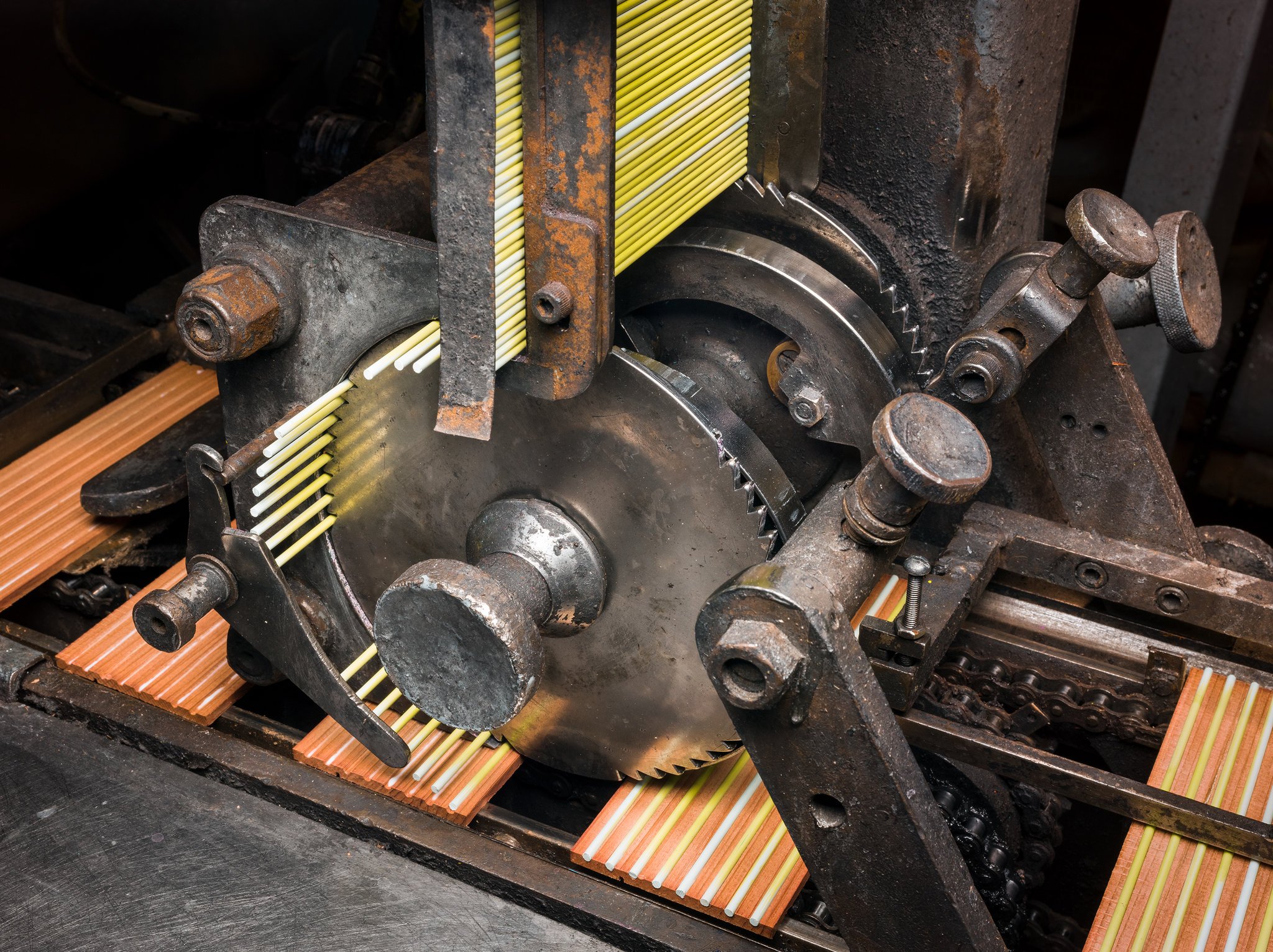

This sandwich still needs to be shaped. A woodworking machine will cut the individual pencils into their desired shape — round, hexagonal or otherwise.

Editing pencils are sharpened at each end: One makes red marks, the other blue. The trays seen here will be turned upside down and dunked in blue paint by a dipper machine, marking the blue half.

Ferrules — the metal bands that cinch around the bases of erasers — are loaded onto a conveyor and sent to a tipping machine.